Special Purpose Machines

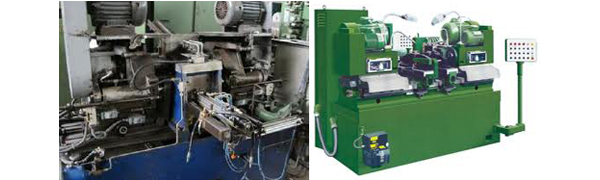

Gear Deburring Machine

ARMS - DBR - 05 is specially designed for removing sharp edges of gears used in gear pumps to improve the quality and life of the gear pumps. This machine works in fully automatic cycle for 5 components simultaneously.

Salient Features

- 5 live Spindles and 5 hydraulic tail stocks for holding the gears automatically

- Spindles rotates with single motor through a gear train

- Double wheel heads with 5 wheels each, on top and bottom to complete both sides operations simultaneously.

- Twin pallets for loading and unloading of components to reduce the cycle time. Human intervention is required

- only to place the components on the pallet during machine operation

- Hi-tech hydraulic power unit and electrical control panel to run the machine in fully automatic cycle.

- Single cycle start button to complete the entire cycle.

- Adjustable wheel heads and tail stocks to accommodate different type of components with minimized setting time.

Advantages

- Improves quality and life of gear pumps

- Greater efficiency of gear pumps

- Identical profiles on all gears

- Improves productivity

- Less human intervention

Super Finishing Machines

ARMS — SF — 200 twin headed super finishing machine is designed for super finishing of cylindrical components to achieve better surface finish for improving the quality, and life of the produds. Thb machine works bi fully automatic with separate roughing and finishing cycle.

Salient features

- High precision live Spindle and hydraulic tail stock for holding the components between centre

- Infinkely variable Spindle speed through VF Drive with separate preset speeds for roughing and finishing cycle.

- Double vibratory heads mounted 90 degree apart for roughing and finishing operation

- R2 volue of up to 0.2 micron ( Pa value of 0.02 micron ) possible

- Hurnan intervention is required only to load / unload the components to the machine (Automatic loading / unloading is optional).

- Hi-tech hydraulic power unit and electrical condol panel to run the machine in fully automatic cycle.

- Single cyole gaa hot, to complete the entire cycle.

Advantages

- Improved surface finish up to Rz value of 2.0 microns

- Greater efficiency of products

- Consistent Rz value en all components

- Improves productivity

- Less human intervention

Applications

- Gear pump shafts

- Valves and valve spools

- Bearing rollers

- Plug gauges

- Pomp pishons

- Piston rods etc.

Assembly line automation

When you need a custom assembly line, ARMS has the experience and product line to be your single source. Regardless of what you manufacture, ARMS sales and engineering team can put together a system to exceed your expectations. From a single conveyor, to multiple custom conveyors integrated in sequence, you can be confident that your production line will start-up on time and on budget. And, if you prefer we use certain brand, type, or size components to align with your plant maintenance strategy, we will design our equipment accordingly. In designing your assembly line, we will utilize our pre-engineered and proven conveyors such as slider beds, chain driven roller, belt driven, and slat conveyors which will then be customized and integrated for the application. Platforms of all types, including personnel work stations, are provided when elevation is needed.

Recent Examples of Assembly Line Automation

- gear box assembly line, including a working platform

- gear pump assembly line

- motor assembly line

- Parts Assembly for electronics manufacturer

- Machining operations performing finish grinding, drilling, milling etc

Advantages

- Improves productivity

- Less man power

- Low cost

- Save time

- enhanced productivity

- improved quality

- safety

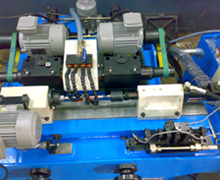

Automatic Test rigs

Optimizing the advanced technology, we are engaged in manufacturing a wide range of test rigs for hydraulic cylinders, valves, pumps, motors, etc. These test rigs are designed for testing pressure, leakage, flow, etc., and provided with provision for cyclic and fatigue tests. Precision engineered, these are made in strict compliance with the relevant industrial standards.

Manufactured using latest technology with quality raw materials, these products are widely used in Automobile, Electrical and Electronic Industries. We have appointed a team of highly skilled professionals, who execute our business operations with dedication and perfection. They ensure optimum satisfaction to our clients by maintaining standard quality policy and ethical business practices.

Due to our commitment and passion, we have earned great appreciation all over the world in from of numerous clients. They have provided us an opportunity to serve them so long that has, eventually encourages us to perform the best. Automatic Test rigs is mainly used to check the valves, machinery components and some precision components checking purpose used this machine .it is very easy to find the problems

Advantages

- Improves productivity

- Enhanced productivity

- Improved quality

Facing and centering machine

Centering and Facing Machines are most suitable for centering, chamfering and external turning of the two ends simultaneously of the bar stock, such as camshafts, crankshafts, motor-shafts, universal joint, spinders etc. ensuring perfect alignment of centers, accurate length and true end. These are available in four length capacities. The combined centering and facing operation saves machine time, handling time and floor space. The machine has two Hydraulic operated self centering work holding vices with push button control. The cutting cycle is operated with push button on a fast approach slow feed and rapid return basis.

Advantages

- Improves productivity

- Less man power

- Low cost

- Save time

- enhanced productivity

- improved quality

- safety

Flap wheel testing machine

Optimizing the advanced technology, we are engaged in manufacturing a wide range of testing machines for grinding wheels,flapwheels etc These testing machines are designed for testing wear out,depth of cut, feed rate,max rpm,min rpm, etc., and provided with provision for cyclic and fatigue tests. Precision engineered, these are made in strict compliance with the relevant industrial standards. .The strength of the grinding wheel checking is main purpose of the machine.

Advantages

- Economical

- Improves quality and life of grinding wheels

- Improves productivity

- enhanced productivity

- improved quality

- Unskilled labour

- Safety

Gear face polishing machine

Polishing and buffing are finishing processes for smoothing a gear surface using an abrasive wheel. Polishing has been traditionally done manually. It is as much an art as a science, with great skill required in selection of abrasive medium, work speeds, and applying the right force in the right direction to achieve the required uniform finish. we can offer the right technology for polishing a large variety of components, Specially designed for rounding off sharp edges of gear used in gear pumps to improve the quality and life of the gear pumps. This machine works in fully automatic cycle Gear face polishing machine can be fully automated. This helps to continue the jobs without intervention of manpower.

Advantages

- Economical

- Improves quality and life of gear pumps

- Indentical profiles on all gears

- Improves productivity

- enhanced productivity

- improved quality

- Unskilled labour

- saftey

Pipe Boring Machine

ARMS is developed PLC or CNC controlled Double ended Pipe end boring and through boring machine . This is used for Conveyer roller pipe boring ,Facing & Chamfering can be done at both ends in one setting with in seconds. This machine base is fabricated and slides are hardened and ground . This slide moves with ball screw &nut with help of servomotor at both ends. One end provided adjustable type for length setting and both ends has got spindle heads and self centering clamping devices for holding the pipe. This machine is totally operated by servo with CNC or servo with PL with HMI control system. Spindle Heads construction with high precision bearings, spindle is case hardened and ground. spindle rpm is infinitely variable through VFD. Self centering clamping devices operated by hydraulic system . The machine have provided centralized lubrication and high pressure coolant flush out provided through cutter heads. Automatic job loading and unloading with out manual intervention also possible

OUR PRODUCTS

- Hydraulic Steady Rest

- Self Centering Steady Rest

- Steady Rest for CNC Lathe

- Steady Rest for Grinding

- Hydraulic Press

- Hydraulic Honing Machines

- Super Finishing Machines

- Super Finishing Attachment

- Over head Gantries

- Machine Tool Automation

- Robo Arms

- Pallet Changer

- Parking Solutions

- Special Purpose Machines