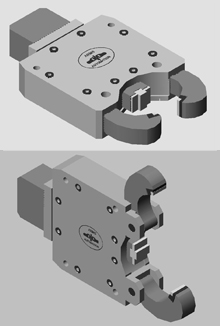

Steady Rest for Grinding

Arms grinding steady rest is an apt design for holding long slender cylindrical jobs. This steady can be specially used in CNC as well as mannual grinding machine by it’s compatibility of programming & interfacing with the cnc system. Arms steady rests are designed to get optimum result in accurate grinding of long slender jobs .Arms steady rests are designed for getting high productivity by eliminating rejection and the setting time of manual steady rests.Arms steady rests are designed according to the customers’ requirement of job sizes. These are hydraulically operated steady rests. Side mounted and rear mounted cylinder designs are also available according to the bed design of machine.Arms steady rests are at par to the international standard by manufacturing & design yet very competitive in price ! These steady rests are dimensionally interchangeable with any other similar models available in the market.

Application

- Machining of Long Slender Shafts

- Automatic Holding of Jobs In CNC grinding Machines.

- Crank Shaft Machining

- For Grinding Applications

Salient Features

- The Steady Rest Can Be Used For Any Machine Including CNC grinders With a Suitable Bracket

- The Steady Can Also Be Used As A Travelling Steady Hence No Need Of A Follower Rest !!!

- High centering accuracy because *real cam technology* used

- Pass through grinding possible

- Continues support while part being ground

- Repeatability Is Within 2 Microns !!!!!!!!

Working principle

The steady rest consists of 3 arms assembled in a steel body with carbide pads at the arms for holding the work piece. The centre one brings the other two arms in a circular movement to hold the center of the work piece .This helps to get the repeatability, consistency and centering accuracy The centre arm is operated by a hydraulic,pneumatic cylinder or servo motor.

TYPES OF GRINDING STEADY REST

- Hydraulic Self Centering Steady rest with rear mounted cylinder

- Pneumatic Self Centering Steady rest

- Self Centering Steady rest with servo control

- Hydraulic Self Centering steady rest for crank shaft grinding

- Hydraulic Self Centering steady rest for cam shafts

- Hydraulic Self Centering steady rest for vertical loading

STANDARD RANGE OF GRINDING STEADY REST ARE THE FOLLOWING

| MODEL NO. | DIAMETER RANGE | APPLICATIONS |

| AGU 1 | 10 to 30mm | FOR NORMAL GRINDING APPLICATION |

| AGU 2 | 20 to 60mm | |

| AGUV 1 | 10 to 30mm | FOR NORMAL GRINDING APPLICATION WITH VERTICAL LOADING |

| AGUV 2 | 20 to 60mm | |

| ACU 1/ACUV1 | 40 to 70mm | FOR CRANK SHAFT GRINDING APPLICATION WITH OR WITH OUT VERTICAL LOADING |

| ACU 2/ACUV2 | 45 to 110mm | |

| ACU 3/ACUV3 | 70 to 150mm | |

| ACU 4/ACUV4 | 50 to 200mm |

How ever the steady rest can be designed as per customer’s requirement

OUR PRODUCTS

- Hydraulic Steady Rest

- Self Centering Steady Rest

- Steady Rest for CNC Lathe

- Steady Rest for Grinding

- Hydraulic Press

- Hydraulic Honing Machines

- Super Finishing Machines

- Super Finishing Attachment

- Over head Gantries

- Machine Tool Automation

- Robo Arms

- Pallet Changer

- Parking Solutions

- Special Purpose Machines